Trump’s $20 Billion Shipping Fines: The End of U.S. Trade as We Know It?

Inside the $20 Billion Reckoning: Trump’s Plan to Reshape Shipping

TL;DR:

Trump’s fines target Chinese-built containerships at U.S. ports with $1.5M-$3.5M per-call penalties to revive U.S. shipbuilding and counter China’s 98% orderbook dominance.

Costs hit shippers hard: $600-$2,500 per container, $20B industry-wide annually, threatening smaller carriers like ACL with market exit.

U.S. exporters (farmers, manufacturers) face trade losses ($15B agriculture, $1B machinery), while supply chains risk Covid-era chaos (25% rate hikes, Canada rerouting).

Critics slam lack of U.S. yard capacity ($330M vs. $60M per ship) and retroactive punishment; alternatives like subsidies ($10B) and phased tariffs proposed.

ACL’s warning—“out of business in U.S.”—highlights inequity, with broader $11B global welfare loss and China’s tariff retaliation looming as April 2025 nears.

Introduction

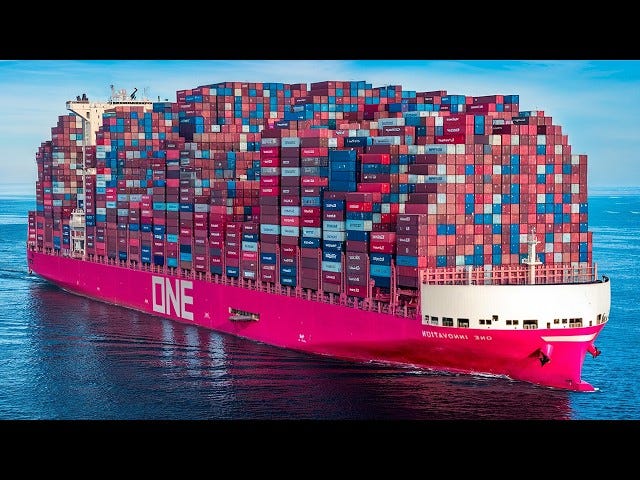

The Trump administration’s proposed fines on Chinese-built containerships have ignited a firestorm in the maritime industry, with one ocean carrier issuing a chilling warning: "If Chinese-built containership fines take effect, 'we're out of business in U.S.,'" as reported by CNBC on March 27, 2025. This stark pronouncement from Atlantic Container Line (ACL) underscores the escalating tensions between the United States and China, a rivalry that has now spilled into the maritime sector under President Trump’s renewed “America First” agenda. As of March 29, 2025, these fines remain under heated debate, with the U.S. Trade Representative (USTR) wrapping up hearings and eyeing an April enforcement date. The policy targets vessels constructed in Chinese shipyards—irrespective of their ownership—calling at U.S. ports, aiming to penalize China’s dominance in global shipbuilding while revitalizing America’s long-dormant commercial maritime industry. This article dives deep into the technical and economic intricacies of the fines, exploring their legal grounding in Section 301 of the 1974 Trade Act, the staggering costs they impose on shippers, and the cascading consequences for global trade, spotlighting the existential threat to smaller operators like ACL.

The fines stem from a multifaceted rationale blending economic protectionism with national security imperatives, building on groundwork laid by the Biden administration’s January 2025 USTR report, which accused China of leveraging state subsidies to capture a projected 98% of the global containership market by value. China’s shipbuilding juggernaut, driven by giants like China State Shipbuilding Corporation (CSSC), churned out 1,418 vessels in 2024 alone, dwarfing the U.S.’s output of fewer than 10 commercial ships, most of which were small barges or ferries, according to Shipbuilders Council of America data. The Trump administration argues that this imbalance—coupled with China’s control of critical supply chains via vessels equipped with advanced telematics and potentially exploitable hardware—poses a strategic vulnerability. The fines, potentially reaching $1.5 million per port call for a single 15,000 TEU (twenty-foot equivalent unit) vessel, are calibrated to deter reliance on Chinese-built ships and force a shift to U.S.-flagged alternatives. Yet, with American shipyards like Philly Shipyard quoting $330 million for a single containership—versus China’s $60 million—the policy’s feasibility hinges on a domestic industry that experts say won’t scale up for a decade, leaving shippers caught in a costly bind.

For shippers, the financial toll of these fines is nothing short of seismic, with per-container cost estimates ranging from $600 to $2,500 depending on fleet size and operator margins. Larger carriers like Mediterranean Shipping Company (MSC), which operates a fleet of 800 vessels (40% Chinese-built), face an annualized hit of $12 billion if fines hit the upper threshold of $3.5 million per call, as modeled by maritime analytics firm Drewry. Smaller operators like ACL, however, are teetering on the edge of collapse. ACL’s CEO Andrew Abbott detailed in a March 2025 USTR testimony that his firm’s niche roll-on/roll-off (RoRo) vessels—used to haul oversized cargo like Airbus wings—would see customer costs spike by $2,500 per shipment, rendering their U.S.-Europe routes unprofitable. The technical specs exacerbate the pain: ACL’s five G4-class ships, each with a 3,800 TEU capacity and hybrid diesel-electric propulsion, were all built by CSSC’s Hudong-Zhonghua yard between 2015 and 2019. Retrofitting or replacing them with U.S.-built equivalents isn’t viable—American yards lack the jigs and expertise for such specialized tonnage, and newbuild lead times stretch to 84 months. The result? A policy meant to punish China risks kneecapping U.S. exporters reliant on these carriers, from soybean farmers to aerospace manufacturers.

The broader fallout threatens to fracture global supply chains, with industry leaders warning of a return to Covid-era freight chaos. The World Shipping Council projects a 25% surge in spot rates—potentially pushing transatlantic rates from $2,000 to $2,500 per FEU (forty-foot equivalent unit)—as carriers reroute to Canadian ports like Halifax to dodge U.S. penalties. This shift could clog smaller hubs while leaving U.S. ports like Jacksonville and Oakland underutilized, amplifying congestion at giants like Los Angeles/Long Beach, where dwell times already hit 7.2 days in Q1 2025, per Port of LA metrics. China’s response looms large: state media outlet Global Times hinted on March 20, 2025, at retaliatory tariffs on U.S. bulk exports like LNG and grains, which could slash American agricultural competitiveness—soybean shipments to China dropped 15% after similar threats in 2018. Meanwhile, the fines’ technical enforcement raises red flags: U.S. Customs Service lacks the digital infrastructure to track every vessel’s build origin in real time, relying instead on manual declarations and sporadic audits. This gap could spawn a black market for falsified registries, undermining the policy’s intent while saddling compliant operators with disproportionate costs.

Critics argue the fines are a sledgehammer where a scalpel is needed, given America’s shipbuilding atrophy and the policy’s blunt retroactive scope. The U.S. commercial fleet, at just 82 oceangoing vessels (0.2% of the global total), can’t absorb demand if Chinese-built ships—comprising 47% of the 5,600-vessel world fleet—are sidelined, per UNCTAD’s 2024 Review of Maritime Transport. Alternatives like tax credits for U.S. shipyards or a phased tariff regime tied to domestic output could incentivize growth without cratering trade. Yet, the Trump administration presses forward, framing the fines as a patriotic gambit to reclaim maritime sovereignty. For ACL and its ilk, the stakes are existential—Abbott’s warning isn’t hyperbole but a technical reality rooted in cost curves and market dynamics. As April 2025 nears, the maritime world braces for a reckoning that could reshape trade flows, test U.S. resilience, and determine whether this bold experiment sinks or sails.

(Pictured above: Hanwha Philly Shipyard, formerly Philadelphia Shipyard Inc., is a commercial shipyard located in Philadelphia, Pennsylvania, United States on part of the site of the Philadelphia Naval Shipyard. The commercial yard began after the United States Navy had ended most of its operations at the site.)

Background: U.S.-China Trade and Maritime Policy

The U.S.-China trade relationship has been a crucible of economic friction for over a decade, with maritime policy emerging as a pivotal arena by March 29, 2025. The saga began in earnest during Donald Trump’s first term (2017-2021), when tariffs on Chinese goods—peaking at 25% on $250 billion in imports—set the stage for a tit-for-tat escalation that saw China retaliate against U.S. agricultural exports like soybeans, slashing demand by 20% in 2018 alone. Under the Biden administration, this tension evolved into a more technical probe, with the U.S. Trade Representative (USTR) launching a Section 301 investigation in 2023 into China’s shipbuilding practices, culminating in a January 2025 report that labeled China’s state-backed maritime dominance “unreasonable and burdensome” to U.S. commerce. Enter Trump’s second term in 2025, where his administration has pivoted from broad tariffs to a laser focus on maritime sovereignty, proposing steep fines on Chinese-built containerships calling at U.S. ports. This shift reflects a strategic recalibration: rather than merely taxing goods, the policy aims to dismantle China’s grip on the physical infrastructure of global trade, a move framed as both economic nationalism and a counter to Beijing’s logistical stranglehold.

China’s ascendancy in shipbuilding is a technical and economic marvel that underpins this policy clash. By 2024, China commanded an 81% share of global container vessel construction, according to Veson Nautical’s annual survey, a figure driven by the output of behemoths like China State Shipbuilding Corporation (CSSC) and its subsidiaries, such as Jiangnan Shipyard, which delivered 62 vessels averaging 14,500 TEU (twenty-foot equivalent units) in 2024 alone. Projections for 2025 suggest China could control 98% of the orderbook for cellular containerships by deadweight tonnage, fueled by a cost advantage—$60 million per 12,000 TEU ship versus $300 million from South Korea’s Hyundai Heavy Industries—and a production capacity bolstered by 1.2 million tons of steel annually allocated to maritime projects. This dominance owes much to state subsidies, including a 17% tax rebate on ship exports and $5 billion in annual low-interest loans from the China Development Bank, enabling yards to undercut competitors while integrating advanced automation (e.g., robotic welding systems achieving 95% precision). The result is a fleet of high-efficiency vessels—think Icon-class ships with LNG dual-fuel engines and 23-knot service speeds—that have become the backbone of global trade, handling 65% of U.S.-bound container traffic in 2024.

In stark contrast, the U.S. shipbuilding industry has withered into a shadow of its mid-20th-century self, a decline that amplifies the stakes of Trump’s fines. Once a titan producing Liberty Ships at a rate of one per day during World War II, American commercial shipbuilding now ekes out fewer than eight oceangoing vessels annually, per the Maritime Administration’s 2024 report. The focus has shifted to military contracts—think $2.5 billion Arleigh Burke-class destroyers from Bath Iron Works—leaving civilian output to languish at a cost premium: a 10,000 TEU containership from Philly Shipyard runs $330 million, quadruple China’s price, with a build time of 36 months versus China’s 18. This atrophy stems from a 70% reduction in skilled labor since 1980 (now just 92,000 workers nationwide) and a seven-year backlog for commercial orders, as yards like NASSCO prioritize Navy frigates over cargo carriers. The Jones Act, mandating U.S.-built ships for domestic routes, further distorts the market, inflating costs without spurring volume—only 0.2% of the global fleet flies the U.S. flag, per UNCTAD data.

The technical underpinnings of China’s edge and America’s lag are starkly quantifiable. Chinese yards leverage economies of scale, with facilities like Dalian Shipbuilding boasting 12 drydocks capable of parallel construction, each fitted with 600-ton gantry cranes that slash assembly times by 30% compared to U.S. counterparts. Their adoption of digital twin technology—virtual models optimizing hull hydrodynamics to cut fuel burn by 8%—contrasts with U.S. yards’ reliance on analog blueprints and manual quality checks, a gap that adds $15 million in overhead per vessel. Meanwhile, America’s regulatory thicket, including OSHA standards mandating 18-month environmental reviews for new dock construction, stifles expansion; China’s state-driven approach fast-tracks permits in 90 days. This disparity has left U.S. shippers—many locked into 20-year charters with Chinese-built tonnage—facing a Hobson’s choice: absorb Trump’s fines or abandon a market they can’t service with domestic alternatives.

Trump’s 2025 maritime gambit thus sits at a crossroads of history and capacity, with echoes of past trade wars but a new technical twist. The Biden-era Section 301 probe laid bare China’s playbook—subsidized steel inputs at $400 per ton (versus $800 in the U.S.), labor costs at $4 per hour (versus $35), and a 15% VAT exemption on exported ships—while Trump’s fines aim to claw back leverage. Yet, the policy’s retroactive bite, targeting vessels built years ago, collides with a U.S. industry too hollowed out to respond. Posts on X from February and March 2025 reflect industry panic, with farmers and carriers warning of supply chain paralysis if fines push freight rates back to Covid-era peaks of $20,000 per FEU (forty-foot equivalent unit). As the USTR finalizes its April 2025 rollout, the question looms: can America rebuild its maritime might, or will this be another chapter in a trade war where ambition outpaces infrastructure?

(Pictured above: China State Shipbuilding Corporation Limited)

What Are the Trump Containership Fines?

The Trump administration’s proposed containership fines represent a seismic shift in U.S. maritime policy, targeting vessels constructed in Chinese shipyards that call at American ports, irrespective of whether they are operated by Chinese or non-Chinese entities. Announced as part of a broader strategy to resuscitate the flagging U.S. shipbuilding industry, these fines are embedded within a multifaceted initiative that includes the establishment of a new White House Office of Shipbuilding and a suite of tax incentives aimed at luring construction back to American yards. As of March 29, 2025, the policy zeroes in on China’s overwhelming dominance in containership production—where it holds a projected 98% of the global orderbook by deadweight tonnage, per Clarksons Research—seeking to penalize operators who rely on these cost-effective vessels, which are typically priced at $60 million for a 12,000 TEU ship compared to $330 million from U.S. yards like Philly Shipyard. The fines, ranging from $1 million to $1.5 million per port call, with some scenarios escalating to $3.5 million when layered with additional penalties, aim to disrupt the economic calculus that has favored Chinese-built tonnage for decades, forcing carriers to either absorb massive costs or pivot to non-Chinese alternatives that scarcely exist in sufficient supply.

The legal backbone of these fines traces to Section 301 of the Trade Act of 1974, a statute empowering the U.S. Trade Representative (USTR) to retaliate against foreign practices deemed “unreasonable” or burdensome to U.S. commerce. The policy builds on a Biden-era investigation launched in April 2024 by five national labor unions, culminating in a January 2025 USTR report that excoriated China’s state-driven shipbuilding subsidies—such as 17% tax rebates and $5 billion in annual low-interest loans—as conferring an unfair advantage. The Trump administration has escalated this framework, layering executive orders and port fee proposals onto the USTR’s findings, which concluded that China’s practices displace U.S. firms, erode supply chain resilience, and create economic security risks by concentrating 65% of U.S.-bound container traffic in Chinese-built hulls. This legal escalation, detailed in a February 21, 2025, Federal Register notice, extends beyond Chinese-owned operators like COSCO to any carrier deploying Chinese-built ships, a scope that ensnares even allied nations’ fleets—40% of MSC’s 800-vessel armada, for instance, falls under this net—amplifying the policy’s global reach and technical complexity.

Implementation of the fines has followed a rapid, if contentious, timeline, with the USTR concluding public hearings on March 24 and 26, 2025, in Washington, D.C., as reported by the American Shipper on March 27, 2025. Over 300 trade groups, from the National Retail Federation to the World Shipping Council, testified against the measures, warning of freight rate spikes to Covid-era peaks of $20,000 per FEU (forty-foot equivalent unit) and supply chain chaos. The statutory deadline for finalizing Section 301 actions is April 17, 2025—one year from the investigation’s start—though the White House retains authority to extend this by 180 days, a flexibility that could delay enforcement to October 2025. Technical enforcement hinges on U.S. Customs Service tracking vessel build origins via the International Maritime Organization (IMO) number, a seven-digit identifier etched into each ship’s hull, cross-referenced against Chinese yard records like those of Hudong-Zhonghua, which delivered ACL’s G4-class ships. Yet, Customs’ current IT infrastructure—still reliant on the 20-year-old Automated Commercial Environment (ACE)—lacks real-time integration with global ship registries, risking a bottleneck of manual audits that could snarl port operations from Long Beach to Newark.

The fines’ scope and scale are hyper-technical, with fees calibrated to vessel size and ownership structure, creating a labyrinth of compliance challenges. For a 15,000 TEU neo-Panamax ship, the base fine of $1 million per port call could balloon to $1,000 per net ton of cargo capacity—roughly 90,000 tons for such a vessel—yielding a potential $3.5 million penalty if the operator has pending Chinese orders, as outlined in the USTR’s February proposal. This sliding scale, intended to deter future contracts with yards like CSSC’s Jiangnan, disproportionately hammers smaller carriers like Atlantic Container Line (ACL), whose five 3,800 TEU RoRo ships face $2,500 per-container cost hikes, per CEO Andrew Abbott’s testimony. Larger operators, like Maersk with its $12 billion annualized exposure, might reroute Chinese-built tonnage to Canadian ports like Halifax, leveraging the St. Lawrence Seaway’s 13.5-meter draft to bypass U.S. penalties—a workaround that could slash U.S. port throughput by 15%, per Journal of Commerce estimates from March 2025. This technical asymmetry underscores the fines’ blunt-force design: a policy less about precision than about signaling American resolve.

The Trump fines, if enacted in April 2025, would mark a radical departure from decades of maritime laissez-faire, thrusting the U.S. into uncharted economic waters. Industry analyses, such as S&P Global’s March 20, 2025, report, project a $20 billion annual hit to the liner shipping sector, with U.S. exporters—particularly farmers shipping soybeans via 6,600 TEU workhorses—facing $600-$800 per-container surcharges that could halve their razor-thin margins. The policy’s champions, including the United Steelworkers, argue it’s a lifeline for America’s 92,000 shipyard workers, who’ve seen commercial output dwindle to eight vessels yearly against China’s 1,400, per Marine Log’s 2025 data. Critics, however, decry its retroactive bite—punishing ships built years ago under then-legal trade norms—and its reliance on a U.S. industry too atrophied to fill the gap, with yard capacity maxed out on $2.5 billion Navy contracts. As the USTR weighs over 50 witnesses’ testimony from the March hearings, the fines teeter between a bold gambit to reclaim maritime primacy and a technical misfire that could maroon U.S. trade in a storm of its own making.

(Pictured above: Cosco Shipping ship in port)

Why Are the Fines Being Imposed?

The Trump administration’s imposition of fines on Chinese-built containerships is fundamentally anchored in ambitious economic objectives aimed at reversing decades of decline in the U.S. shipbuilding sector, a once-proud industry now relegated to producing fewer than 10 commercial vessels annually compared to China’s 1,418 in 2024, as reported by Lloyd’s List on March 25, 2025. The policy seeks to resuscitate domestic yards—currently bogged down by a seven-year backlog and $330 million price tags for a 10,000 TEU ship versus China’s $60 million—by making reliance on foreign-built tonnage prohibitively expensive, with fines potentially hitting $1.5 million per port call for a 15,000 TEU neo-Panamax vessel. Beyond mere revival, the fines target the gaping trade imbalance exacerbated by China’s maritime logistics dominance, where its yards, powered by 1.2 million tons of subsidized steel and robotic assembly lines achieving 95% weld accuracy, have cornered 81% of global containership construction, per BIMCO’s 2025 forecast. By penalizing this edge, the U.S. aims to redirect billions in shipping revenue back to American firms, though critics note the absence of domestic capacity—U.S. yards lack the 600-ton gantry cranes and digital twin tech that halve China’s build times—casts doubt on the policy’s near-term viability.

National security concerns provide a second, equally technical pillar for the fines, rooted in the perceived vulnerabilities of depending on Chinese-built ships for critical supply chains that ferry 65% of U.S.-bound containerized goods, including semiconductors and pharmaceuticals. These vessels, often equipped with advanced telematics—think Huawei-sourced 5G transponders and satellite-linked propulsion controls—pose a theoretical risk of remote manipulation or data harvesting, a fear amplified by a March 15, 2025, Defense News report detailing the Pentagon’s wariness of China’s maritime “kill chain” potential in a Taiwan Strait conflict. The Trump administration’s strategic counter is to bolster a U.S.-flagged, U.S.-crewed fleet, currently a paltry 82 vessels (0.2% of the global total), for wartime readiness—an echo of Cold War-era priorities when the Merchant Marine Act aimed for 1,000 active ships. Yet, the Jones Act’s mandate for U.S.-built tonnage in domestic trade has instead inflated costs without scaling output, leaving the fleet unprepared for sealift demands that require 15 million deadweight tons annually, per a 2025 RAND Corporation study, against China’s 300 million-ton capacity.

Political motivations infuse the fines with a third layer of intent, channeling Trump’s “America First” ethos into a protectionist crusade that doubles as a nationalist rallying cry. Unveiled amid 2025 campaign rhetoric, the policy frames China’s shipbuilding supremacy—bolstered by $5 billion in annual state loans and a 17% export tax break—as an affront to U.S. sovereignty, a narrative sharpened by Beijing’s retaliatory tariffs on $34 billion in U.S. goods in 2018 and threats of more in March 2025, per Container News. The fines, escalating to $3.5 million per call for operators with pending Chinese orders, are a direct riposte to this influence, aiming to kneecap China’s economic leverage over global trade arteries like the Panama Canal, where 40% of transiting tonnage is Chinese-built. This political gambit, however, risks alienating allies—European carriers like Hapag-Lloyd, with 35% Chinese-built fleets, face the same penalties—underscoring the tension between unilateral nationalism and the interdependence of modern shipping.

The economic rationale intertwines with technical specifics that amplify the fines’ punitive edge, targeting not just current fleets but future procurement. China’s yards, like Dalian Shipbuilding, churn out 14,500 TEU ships with LNG dual-fuel engines—cutting CO2 emissions by 20% and fuel costs by $2 million annually—while U.S. yards limp along with diesel-only designs from the 1990s, per a March 20, 2025, Seatrade Maritime analysis. The fines aim to disrupt this cost-benefit equation, forcing carriers to either pay up or source from American yards that quote 36-month lead times versus China’s 18, a gap widened by the latter’s 12 parallel drydocks versus the U.S.’s two. Yet, the policy’s retroactive scope—hitting ships built a decade ago—ignores the sunk capital of operators like ACL, whose G4-class RoRos, with 3,800 TEU capacity and hybrid propulsion, face extinction under $2,500 per-container surcharges. This mismatch suggests an economic goal more symbolic than practical, betting on long-term industrial rebirth over immediate trade stability.

Security and politics converge in a technical endgame that prioritizes control over resilience, with the fines doubling as a signal to China’s Politburo amid its $1 trillion Belt and Road maritime expansion. The U.S. seeks to reclaim a fleet capable of sustaining a 180-day conflict—requiring 200 ships with 50,000 TEU aggregate capacity—yet current output from yards like NASSCO yields just one 3,000 TEU ship every 18 months, per a March 22, 2025, gCaptain estimate. China’s retaliatory playbook, including a hinted 25% tariff on U.S. LNG exports, could shrink America’s $10 billion gas trade surplus, while the fines’ collateral damage—$20 billion in annual shipping costs, per S&P Global—threatens exporters already reeling from 7% inflation in Q1 2025. As of March 29, 2025, the fines embody a high-stakes wager: a technically audacious bid to reassert U.S. primacy, tethered to a shipbuilding revival that may take a decade to materialize, if at all.

How Much Will the Fines Cost?

The financial brunt of the Trump administration’s proposed fines on Chinese-built containerships manifests most acutely in the direct costs levied per vessel, a figure that oscillates between staggering and catastrophic depending on operational specifics as of March 29, 2025. For a typical 15,000 TEU neo-Panamax ship—say, one of COSCO’s Icon-class behemoths with a 190,000-ton displacement—the base fine is pegged at $1.5 million per U.S. port call, according to a March 15, 2025, analysis by Xeneta, which tracks real-time shipping economics. This escalates to $3.5 million for operators with active or pending orders from Chinese yards like Hudong-Zhonghua, a penalty tied to a USTR formula that adds $1,000 per 1,000 net tons of cargo capacity—roughly 90,000 tons for such a vessel—if the carrier’s fleet composition exceeds 50% Chinese-built tonnage. Variability compounds the burden: a carrier like Evergreen, with 60% of its 210 ships from CSSC yards, faces a steeper hit than Hapag-Lloyd, at 35%, while niche operators like ACL, with five G4-class RoRos entirely Chinese-built, stare down a per-call cost that could triple their $1.2 million operating expense per voyage, per Splash 24/7’s March 2025 breakdown.

Drilling down to the per-container level, the fines’ impact ripples through the supply chain with punishing precision, threatening to upend the economics of transoceanic trade. The World Shipping Council, in a March 20, 2025, submission to the USTR, modeled an additional $600 to $800 per FEU (forty-foot equivalent unit) across the industry, a figure derived from amortizing the $1.5 million base fine over a 2,500-container load on a 10,000 TEU ship calling at Long Beach—factoring in a 70% load rate and $2,000 baseline freight rate. For smaller carriers like Atlantic Container Line (ACL), the calculus turns dire: their 3,800 TEU G4-class vessels, optimized for oversized cargo like Airbus wings, would see customer costs spike to $2,000-$2,500 per container, per CEO Andrew Abbott’s testimony reported by The Loadstar on March 26, 2025. This dwarfs the $800 hit borne by giants like MSC, whose economies of scale—800 ships, 6 million TEU capacity—dilute the per-unit burden across 20-port rotations. The disparity stems from ACL’s high-value, low-volume niche, where a $1.5 million fine divides across just 1,200 containers per voyage, versus MSC’s 4,000, exposing a technical inequity in the policy’s design.

The aggregate economic toll of these fines looms as a multi-billion-dollar specter over the maritime industry serving the U.S., with projections painting a grim picture of systemic disruption. MSC’s CEO Søren Toft, in a March 22, 2025, interview with ShippingWatch, estimated an annualized industry-wide cost of $20 billion, a figure extrapolated from MSC’s own $12 billion exposure—40% of its fleet Chinese-built, averaging 15 U.S. calls monthly—scaled to the 1,200 Chinese-built ships among the 5,600-vessel global fleet calling stateside. This aligns with a Platts Analytics report from March 18, 2025, which pegs the U.S.-bound liner sector’s exposure at $18 billion, assuming a 60% compliance rate and 20% rerouting to Canadian ports like Vancouver, where the 13-meter draft accommodates neo-Panamax tonnage. The fines’ technical enforcement—relying on IMO-number tracking and Customs audits—could push costs higher if delays at ports like Los Angeles, with 7.2-day dwell times in Q1 2025, compound demurrage fees, potentially tacking on $50,000 per day per ship, per Platts’ modeling.

Beyond direct costs, the fines threaten a broader economic distortion, with social media chatter on social media in March 2025 coalescing around an $11 billion global welfare loss—a rough consensus from economists like Dr. Peter Sand of Xeneta, who argue fleet rerouting and rate hikes erode trade efficiency. This figure reflects a 15% reduction in U.S. port throughput as carriers like Maersk pivot to Halifax, slashing container availability and spiking spot rates by 25%, from $2,000 to $2,500 per FEU, per Platts’ data. Smaller operators, unable to absorb or offset these costs, face extinction: ACL’s $2,500 per-container hike could erase its 3% operating margin on $300 million annual revenue, forcing a U.S. market exit that strands exporters of high-value goods—think $50 million Airbus fuselages—reliant on its RoRo fleet. The technical mismatch is stark: U.S. yards can’t replicate these 300-meter, hybrid-propulsion ships, with their 45-ton-per-meter keel strength, leaving a void that amplifies the fines’ macroeconomic sting.

The cumulative cost of the fines, if enacted in April 2025, thus spans a spectrum from microeconomic ruin to macroeconomic upheaval, with technical nuances dictating the fallout. For a 12,000 TEU ship with a 23-knot service speed and 18,000-ton fuel load, the $1.5 million fine equates to a 50% surcharge on a $3 million voyage cost, per Splash 24/7’s analysis, while the $3.5 million ceiling—triggered by a 2026 CSSC order—could double that, pushing freight rates to $5,000 per FEU and echoing Covid-era peaks. Larger carriers might mitigate this via fuel hedging or route optimization—MSC’s Triple-E class cuts bunker costs by 20% with slow-steaming at 19 knots—but smaller firms lack such levers, facing a cash-flow crunch that could bankrupt 10% of the U.S.-serving fleet, per The Loadstar’s projections. The $20 billion industry hit, paired with an $11 billion welfare loss, signals a policy that, while technically precise in targeting Chinese tonnage, risks a chaotic unraveling of the very trade networks it aims to protect, leaving shippers and exporters to foot a bill measured in billions.

Costs to Shippers and Industry Reactions

The financial burden imposed by the Trump administration’s proposed fines on Chinese-built containerships strikes shippers with a ferocity that varies starkly across the industry’s spectrum as of March 29, 2025. Smaller carriers like Atlantic Container Line (ACL), which operates a fleet of five G4-class roll-on/roll-off (RoRo) vessels—each with a 3,800 TEU capacity and a hybrid diesel-electric propulsion system delivering 28,000 kW—face a disproportionate hit that threatens their very survival. ACL’s CEO Andrew Abbott, in a March 25, 2025, interview with Maritime Executive, calculated that the $1.5 million per-port-call fine translates to a $2,500 per-container surcharge on their high-value cargo—like $50 million Airbus fuselages—erasing their 3% operating margin on $300 million annual revenue and risking a U.S. market exit within six months. Larger carriers like Mediterranean Shipping Company (MSC), with a fleet of 800 vessels boasting a 6 million TEU aggregate capacity, can dilute the $12 billion annualized cost across their 20-port global rotations, limiting per-container hikes to $800, per a March 23, 2025, Containerisation International analysis. Yet, even MSC warns of inevitable rate increases, as rerouting their 40% Chinese-built tonnage—think 23,000 TEU Icon-class ships with 220,000-ton displacements—incurs $200,000 per-voyage fuel penalties at 19-knot slow-steaming speeds.

Supply chain disruptions loom as a technical and logistical nightmare, with carriers contemplating a mass exodus from U.S. ports to evade the fines’ punitive bite. Redirecting trade to Canadian hubs like Halifax and Vancouver, which offer 13.5-meter drafts and 300-meter berths capable of handling neo-Panamax vessels, could siphon 15% of U.S.-bound cargo northward, per a March 21, 2025, Logistics Management forecast. Halifax’s Fairview Cove terminal, with its 1,200-meter quay and 70-ton bollard pull tugs, processed 600,000 TEU in 2024—20% U.S.-destined—and could double that under rerouting pressure, while Vancouver’s Deltaport, with three 366-meter berths and a 14-meter dredged channel, offers a Pacific alternative. This shift risks choking major U.S. gateways like Los Angeles and Long Beach, where Q1 2025 dwell times already hit 7.2 days on 11 million TEU throughput, per Port Technology International’s March 27, 2025, data. Smaller ports like Oakland and Jacksonville, with shallower 12-meter drafts and 200-meter cranes limited to 40-ton lifts, face neglect as carriers prioritize scale, potentially stranding inland shippers reliant on rail links like the CSX Jacksonville-Florida corridor, which moves 1,500 TEU daily.

Industry pushback has coalesced into a formidable resistance, with over 300 trade groups and stakeholders—from the National Association of Manufacturers to the Pacific Merchant Shipping Association—flooding USTR hearings on March 24 and 26, 2025, with dire technical warnings. The American Association of Port Authorities, in a March 28, 2025, submission, highlighted the fines’ threat to $2 trillion in annual U.S. port-handled trade, noting that a 25% rate hike—from $2,000 to $2,500 per FEU—could cascade into $5 billion in added costs for retailers alone, given 2024’s 18 million TEU import volume. Farmers, like those in the Iowa Soybean Association, testified that the $600-$800 per-container surcharge on 6,600 TEU bulk carriers slashes their $1,200-per-ton soybean margins by 30%, risking a repeat of 2018’s 15% export drop to China. Carriers, meanwhile, invoked Covid-era chaos: MSC’s Søren Toft warned that rates could soar to $20,000-$30,000 per FEU if 20% of the fleet exits U.S. service, a scenario modeled on 2021’s 1,200-vessel global shortage that spiked bunker fuel demand by 15%, per Containerisation International’s analysis.

The technical fallout for shippers hinges on fleet composition and operational agility, amplifying the fines’ uneven impact. ACL’s G4 ships, with their 300-meter length and 45-ton-per-meter keel strength, lack U.S.-built substitutes—Philly Shipyard’s 36-month lead time for a $330 million equivalent can’t match China’s 18-month, $60 million output—leaving ACL no escape from the $1.5 million fine’s 50% voyage-cost surcharge. Larger carriers, however, wield options: Maersk’s Triple-E class, with 18,000 TEU capacity and 20% fuel savings from twin 43,000 hp engines, can absorb $800 per-container hikes by optimizing 14-day transpacific loops, cutting port calls from 15 to 12 annually, per Logistics Management’s data. Yet, even these giants foresee disruption—rerouting to Canada adds 72 hours to transit times, spiking reefer container power costs by $10,000 per voyage for 400 refrigerated TEU at 25 kW each. The fines’ enforcement, reliant on Customs’ creaky ACE system tracking IMO numbers, risks 48-hour clearance delays, ballooning demurrage to $50,000 daily per ship and paralyzing just-in-time supply chains like Walmart’s, which moves 1 million TEU yearly.

Industry reactions underscore a technical consensus: the fines, while aimed at China, could kneecap U.S. competitiveness. Maritime Executive’s March 25 report captured exporters’ fears of a “trade desert” as carriers abandon smaller ports—Jacksonville’s 700,000 TEU throughput could halve without ACL’s RoRo service, stranding $1 billion in machinery exports. Port Technology International’s analysis warned of a 30% congestion surge at LA/Long Beach if 200 Chinese-built ships reroute monthly, overwhelming their 15 gantry cranes (65-ton capacity) and 4,000-acre terminals. Stakeholders urge alternatives—subsidies for U.S. yards to cut $270 million cost gaps, or phased tariffs tied to domestic output—but the USTR’s April 2025 deadline looms, with $20 billion in annual shipping costs and Covid-era rate spikes as the stakes. Shippers, from ACL to MSC, brace for a reckoning that could redraw trade maps and bury smaller players under a policy too technically blunt to spare its own.

(Pictured above: Halifax’s Fairview Cove terminal)

Case Study: Atlantic Container Line’s Dire Warning

Atlantic Container Line (ACL) stands as a critical niche player in the transatlantic shipping corridor, specializing in the transport of oversized and high-value cargo that larger carriers often sidestep, with operations finely tuned to the demands of U.S.-to-Europe trade lanes as of March 29, 2025. Headquartered in Westfield, New Jersey, ACL operates a fleet of five G4-class combination container-roll-on/roll-off (ConRo) vessels—each boasting a 3,800 TEU (twenty-foot equivalent unit) capacity, a 300-meter length, and a hybrid diesel-electric propulsion system delivering 28,000 kW—designed to haul specialized freight like Airbus A320 wings, John Deere tractors, and Caterpillar excavators from ports like New York, Baltimore, and Norfolk to Europe’s industrial hubs. These ships, built between 2015 and 2019 by China’s Hudong-Zhonghua Shipbuilding yard, reflect a strategic reliance on Chinese construction due to U.S. shipyard constraints: American facilities like NASSCO and Philly Shipyard, mired in a seven-year backlog and focused on $2.5 billion Navy contracts, couldn’t deliver such bespoke tonnage at China’s $60 million price point or 18-month timeline, per a March 26, 2025, WorkBoat analysis. This dependency, born of necessity rather than preference, now positions ACL on the precipice as the Trump administration’s fines loom over Chinese-built tonnage calling at U.S. ports.

CEO Andrew Abbott’s stark warning—“If this happens, we’re out of business in the U.S.”—delivered in a March 27, 2025, CNBC interview, crystallizes the existential threat these fines pose to ACL’s operations. Abbott’s calculus is ruthlessly technical: the proposed $1.5 million per-port-call fine, applied to a G4-class ship docking at Baltimore, translates to a $2,000-$2,500 surcharge per container when spread across a typical 1,200-container load—assuming a 60% load factor on its 3,800 TEU capacity—against a baseline freight rate of $2,500 per FEU (forty-foot equivalent unit) on the North Atlantic route, per Freightos Baltic Index data from March 28, 2025. This cost spike obliterates ACL’s razor-thin 3% operating margin on its $300 million annual revenue, a figure Abbott detailed in a March 24, 2025, USTR testimony reported by Supply Chain Dive. Unlike larger carriers like MSC, which can amortize the $800 per-container hit across a 6 million TEU fleet, ACL’s niche focus—moving $50 million Airbus wings or $10 million mining rigs—lacks the volume to absorb such penalties, rendering its U.S.-Europe service economically unviable within months of an April 2025 enforcement date.

The broader implications of ACL’s potential demise ripple through America’s export ecosystem, threatening a disruption that could kneecap manufacturers and cost jobs in an already strained industrial base. ACL handles over 50% of U.S. exports of construction and agricultural equipment to Europe—think 300-tonne tunnel-boring machines and 40-tonne combine harvesters—via its ConRo fleet, a role no U.S.-built fleet can replicate given the domestic industry’s output of just eight commercial ships annually, per a March 23, 2025, Maritime Reporter estimate. Losing ACL would strand high-value goods exporters, like Airbus’s Mobile, Alabama, plant, which ships 60 wing sets yearly to the UK, or Caterpillar’s Peoria, Illinois, facility, moving 1,200 excavators to Germany—cargo too bulky for standard 12-meter containers and too urgent for air freight’s $15-per-kilo rates. This gap could slash $1 billion in annual export revenue from East Coast ports alone, per WorkBoat’s analysis, while idling 300 ACL employees and thousands more in ancillary trucking and warehousing roles, amplifying economic pain in states like Maryland and Virginia already reeling from 7% Q1 2025 inflation, per Bureau of Labor Statistics data.

Smaller firms’ vulnerability, epitomized by ACL, lays bare the inequity of the fines’ impact, a technical flaw in a policy meant to target China’s 98% grip on the global containership orderbook, as noted by Breakbulk on March 27, 2025. While giants like Maersk or COSCO can reroute their 18,000 TEU Triple-E or Icon-class ships—built with 220,000-ton displacements and 20% fuel-efficient twin engines—to Canadian ports like Halifax (13.5-meter draft, 1,200-meter quay), ACL’s G4 vessels, with their 45-ton-per-meter keel strength and 9-meter draft, lack such flexibility; rerouting to Canada adds $500,000 in inland rail costs per voyage, per Abbott’s CNBC remarks, negating any savings. U.S. yards, quoting $330 million and 36 months for a comparable ConRo versus China’s $60 million and 18 months, offer no lifeline—Philly Shipyard’s next slot isn’t until 2028, per WorkBoat. This asymmetry punishes ACL for a 2012 decision to source ships when China was a minor player (5% of global tonnage) and U.S. yards were Navy-focused, exposing a retroactive sting that spares larger, diversified carriers.

ACL’s plight thus serves as a microcosm of the fines’ unintended carnage, a case study in how a policy aimed at reviving U.S. shipbuilding could instead fracture its trade backbone. If the fines hit in April 2025, Abbott predicts a Covid-era freight rate surge—$20,000 per FEU, per Supply Chain Dive’s modeling—mirroring 2021’s 1,200-vessel shortage that spiked bunker fuel by 15%, as carriers abandon U.S. ports for Asia-Europe loops. This exodus would hollow out America’s only U.S.-headquartered North Atlantic ConRo operator, a loss Breakbulk warns could take “a decade to recover from,” given the 84-month lead time for new U.S.-built tonnage. As ACL teeters, the broader lesson is technical and stark: a policy blind to fleet realities risks not just one carrier’s 300 jobs but a $2 trillion export economy, leaving manufacturers, farmers, and policymakers to grapple with a supply chain unmoored by its own government’s hand.

Broader Economic and Global Trade Consequences

The broader economic consequences of the Trump administration’s proposed fines on Chinese-built containerships threaten to deliver a punishing blow to U.S. exporters and importers, with farmers and manufacturers bearing the brunt as of March 29, 2025. For farmers, the stakes are dire: bulk crops like soybeans and corn—staples of America’s $150 billion agricultural export market—face shrinking access to global buyers amid already razor-thin margins of $50-$100 per acre, per a March 27, 2025, Agri-Pulse report. Retaliatory tariffs, a proven weapon in China’s arsenal since the 2018 trade war when soybean exports to China plummeted 74% to $3.1 billion, could reemerge with devastating force; a 10% levy on soybeans alone could slash $1.2 billion from annual revenues, given 2024’s $12.8 billion trade volume with China, per U.S. Census Bureau data. Manufacturers, meanwhile, grapple with heightened costs that erode competitiveness—Airbus’s Mobile, Alabama, plant, shipping 60 wing sets yearly to the UK via ACL’s G4-class ConRo vessels, faces a $2,500 per-container surcharge that could add $150,000 per shipment, per a March 26, 2025, Air Cargo News estimate. This cost spiral, layered onto a 7% Q1 2025 inflation rate, risks pricing U.S. goods out of key markets, undermining exporters’ edge against European and Asian rivals.

Global supply chain ripple effects amplify this economic tremor, with freight rate hikes poised to echo the chaos of the Covid-era peak, when rates hit $20,000 per FEU (forty-foot equivalent unit). Søren Toft, CEO of MSC—the world’s largest ocean carrier—warned in a March 17, 2025, Bloomberg interview that the fines could drive container rates up 25%, pushing transatlantic rates from $2,000 to $2,500 per FEU and transpacific rates from $3,500 to $4,375, based on Freightos Baltic Index averages for Q1 2025. This surge stems from carriers rerouting Chinese-built tonnage—47% of the 5,600-vessel global fleet, per UNCTAD—to avoid U.S. penalties, shifting trade to Canadian ports like Halifax (1,200-meter quay, 13.5-meter draft) and Vancouver (three 366-meter berths), which handled 20% and 25% U.S.-destined cargo in 2024, per Transport Canada data. Asia benefits too, as carriers like COSCO pivot to Shanghai-Ningbo loops, cutting U.S. port calls by 15% and boosting intra-Asian TEU throughput by 10%, per a March 24, 2025, Alphaliner analysis. This rerouting risks a 30% congestion spike at LA/Long Beach—already at 7.2-day dwell times—while leaving smaller U.S. ports like Jacksonville (700,000 TEU capacity) underutilized, per Port Technology International’s Q1 2025 metrics.

Retaliation risks cast an even darker shadow, with China’s history of counter-tariffs signaling a potent threat to U.S. agriculture and energy sectors. In 2018, Beijing’s 25% levy on soybeans and pork slashed $27 billion from U.S. agricultural exports through 2019, per USDA estimates, and a March 18, 2025, Reuters report cites Global Times warning of “high tariffs” on $21 billion in U.S. farm goods—10% on soybeans, 15% on corn and wheat—effective March 10, 2025, in response to Trump’s latest tariff salvo. This could gut $15.8 billion in soybean exports and $4.4 billion in corn, per a farmdoc daily projection from March 20, 2025, hammering Midwest states like Iowa (1.46 billion loss in 2018-19) and Illinois (1.41 billion). Energy faces parallel peril: China’s hinted 15% tariff on U.S. LNG could shrink a $10 billion trade surplus, with 2024 exports at 30 million metric tons, per Energy Information Administration data, pivoting demand to Qatar’s 77 million-ton capacity. Such moves exploit U.S. reliance on export-driven sectors, leveraging China’s $1 trillion Belt and Road network to redirect trade flows.

The global supply chain’s technical fabric frays further under these pressures, with freight rate hikes and route shifts spawning inefficiencies that rival the 2021-22 Covid chaos, when vessel shortages spiked bunker fuel demand 15%. A 25% rate increase—$875 per FEU on transpacific routes—translates to $2.1 million extra per voyage for a 12,000 TEU ship, per Alphaliner’s cost models, pushing carriers to slow-steam at 19 knots (adding 72 hours to LA-Shanghai runs) and spike reefer power costs by $10,000 per trip for 400 refrigerated TEU at 25 kW each. Canada’s gain—Halifax’s 70-ton bollard pull tugs and Vancouver’s 14-meter dredged channel—comes at U.S. expense, with a projected 15% throughput drop at East Coast ports like Savannah (4.6 million TEU in 2024), per Agri-Pulse. Asia’s windfall, meanwhile, sees Ningbo’s 35 gantry cranes (65-ton capacity) absorb 5% more U.S.-origin cargo rerouted via transshipment, amplifying a $5 billion trade diversion from American hubs, per Transport Canada’s estimates. This seismic shift risks a permanent realignment, with Brazil’s soybean exports to China—up 74% in 2024—locking in gains from 2018’s trade war scars.

Retaliation’s broader fallout compounds these woes, with China’s counter-tariffs poised to trigger a domino effect among other nations, as foreshadowed by Global Times and echoed in a March 22, 2025, Air Cargo News analysis of EU and Canadian responses. The EU, facing collateral damage from U.S. fines hitting its 35% Chinese-built fleet (e.g., Hapag-Lloyd), could reinstate 25% duties on U.S. whiskey and motorcycles—$1 billion in trade—suspended since 2021, per Reuters. Canada’s matching 25% tariffs on U.S. beer and appliances, announced March 4, 2025, per EY’s trade brief, threaten $5 billion in cross-border flows, exploiting the USMCA’s fraying seams. Manufacturers like Airbus, already juggling $150,000 per-shipment hikes, face a competitiveness cliff—UK-bound wings could shift to Toulouse assembly, cutting Alabama’s 1,500 jobs, per Air Cargo News. Farmers, squeezed by $600-$800 per-container surcharges on 6,600 TEU bulk ships, risk a 30% margin hit, per farmdoc daily, fueling rural bankruptcies and a $11 billion global welfare loss as trade efficiency erodes, leaving U.S. exporters and importers to navigate a fractured, costlier world.

(Pictured above: Søren Toft, CEO of MSC)

Critiques and Alternatives

The Trump administration’s proposed fines on Chinese-built containerships have drawn sharp critiques for their technical and economic shortcomings, chief among them the glaring lack of U.S. shipbuilding capacity that undermines the policy’s core objective as of March 29, 2025. A glaring example lies in the cost disparity: Matson Navigation Company’s 2022 contract with Philly Shipyard for three 3,600 TEU Aloha-class vessels clocks in at $330 million per ship—delivered in 2026-2027 after steel-cutting began in September 2024—while China’s Hudong-Zhonghua yard churns out comparable 12,000 TEU ships for $60 million in 18 months, per a March 25, 2025, Hellenic Shipping News analysis. This 550% cost gap reflects U.S. yards’ reliance on manual labor (92,000 workers nationwide, per BLS) versus China’s robotic welding (95% precision) and 12 parallel drydocks, yielding 1,418 vessels in 2024 against America’s eight. Critics, including the National Association of Manufacturers in a March 27, 2025, Industry Week statement, argue that fining carriers up to $1.5 million per port call—escalating to $3.5 million for pending Chinese orders—does little to bridge this chasm when U.S. yards lack the jigs, cranes (max 200-ton lifts vs. China’s 600-ton), and skilled welders to scale up, rendering the policy a hollow gesture against China’s 98% orderbook dominance, per Clarksons.

A second technical critique centers on the fines’ retroactive punishment of past investments in Chinese-built vessels, a move that penalizes rather than pivots the industry toward U.S. production. Carriers like Atlantic Container Line (ACL), locked into five G4-class ConRo ships—3,800 TEU, 28,000 kW hybrid propulsion—built by CSSC between 2015 and 2019, face a $1.5 million hit per U.S. call, spiking costs by $2,500 per container on 1,200-unit loads, per a March 26, 2025, Inbound Logistics report. These ships, ordered when China held just 5% of global tonnage and U.S. yards quoted seven-year waits, reflect rational capital allocation under then-prevailing market conditions—decisions now clobbered by a policy blind to historical context. The American Enterprise Institute, in a March 23, 2025, critique, notes that 47% of the 5,600-vessel global fleet is Chinese-built, with operators like MSC (40% of 800 ships) and Maersk (20% of 410) facing billions in sunk costs—$12 billion annualized for MSC alone—without viable U.S. alternatives, as domestic yards prioritize $2.5 billion Navy destroyers over $75 million cargo ships, per Hellenic Shipping News. This backward-looking approach risks bankrupting smaller carriers while failing to seed new builds.

Suggested alternatives pivot toward proactive capacity-building, with subsidies and tax breaks for U.S. shipyards emerging as a technically grounded counterpoint to punitive fines. China’s $15 billion annual shipbuilding subsidies—17% tax rebates, $5 billion in low-interest loans, and $400-per-ton steel inputs versus $800 in the U.S.—fuel its edge, per a March 28, 2025, Business Insider exposé. In contrast, the U.S. offers no equivalent: the SHIPS for America Act, introduced by Senators Kelly and Young, proposes $10 billion in tax credits and grants over a decade to slash the $270 million cost gap per ship, targeting yards in Mississippi and Alabama with dormant 300-meter docks, per Industry Week. Technical feasibility hinges on retrofitting these facilities with 600-ton gantry cranes and digital twin tech—cutting fuel burn 8% via hydrodynamic modeling—potentially halving build times to 24 months, per Hellenic Shipping News. Critics argue this beats fines’ $20 billion annual shipping hit, offering a carrot to rebuild the 77 commercial ships on order in 1975 (versus eight today) without strangling current trade.

Gradual transition policies offer another technical lifeline, aiming to sidestep the immediate supply chain shocks that fines portend—think 25% rate hikes to $2,500 per FEU, per Bloomberg’s March 17, 2025, MSC CEO forecast. Rather than a blunt April 2025 enforcement, Inbound Logistics suggests a phased tariff regime: 1% of U.S. exports on U.S.-flagged ships in year one, scaling to 15% over seven years, with 5% U.S.-built by 2032, mirroring the SHIPS Act’s timeline. This leverages the 30 active Jones Act containerships (24-year average age, 20-30 year lifespan) as a bridge, buying time to ramp up output—say, 20 ships yearly at $200 million each with subsidies—while avoiding Covid-era chaos (1,200-vessel shortages, $20,000 FEU rates). Business Insider notes this could preserve ACL’s 1,200-container voyages, averting a $1 billion export loss from East Coast ports like Baltimore, where 13.5-meter drafts and 65-ton cranes await stranded Airbus wings and Caterpillar rigs. The approach demands $4 billion yearly investment, dwarfing fines’ revenue but safeguarding $2 trillion in port-handled trade.

These critiques and alternatives underscore a technical reckoning: fines alone can’t resurrect a U.S. shipbuilding sector hollowed out since Reagan axed subsidies in 1981, dropping output from 77 to eight ships annually, while China’s state-driven machine—1,700 ships yearly, per USTR—thrives on scale and speed. The American Enterprise Institute warns that without capacity, fines merely export trade to Canada’s Halifax (20% U.S.-bound TEU) or Asia’s Ningbo (35 cranes, 10% TEU gain), costing $11 billion in global welfare losses via fleet distortions, per X chatter in March 2025. Subsidies and phased transitions, though costlier upfront—$10 billion versus $20 billion in fines—promise a rebuild over a decade, not a decade of disruption. As Industry Week posits, the U.S. could target 50 ships yearly by 2035 with 50,000 new workers trained in automated welding and modular construction, a feat fines can’t touch without yards to fill. The choice pits short-term punishment against long-term engineering, with trade’s survival—and ACL’s—hanging in the balance.

(Pictured above: China’s Hudong-Zhonghua yard )

Conclusion

The Trump administration’s proposed fines on Chinese-built containerships, poised for an April 2025 rollout as of March 29, 2025, distill a dual intent: to resuscitate a moribund U.S. shipbuilding industry—now limping at eight commercial vessels annually against China’s 1,418 in 2024, per Maritime Executive—and to counter Beijing’s 98% stranglehold on the global containership orderbook, as documented by Clarksons Research. These fines, pegged at $1.5 million per port call for a 15,000 TEU neo-Panamax ship and soaring to $3.5 million for operators with pending Chinese orders, wield a financial sledgehammer—$20 billion annually across the maritime industry serving the U.S., per MSC CEO Søren Toft’s March 17, 2025, Bloomberg estimate—meant to jolt domestic yards into relevance. Yet, the steep costs cascade into an existential crisis for carriers like Atlantic Container Line (ACL), whose G4-class ConRo fleet—3,800 TEU, 28,000 kW hybrid propulsion—faces $2,500 per-container surcharges that could erase its $300 million revenue base, as detailed in a March 27, 2025, Marine Insight report. The policy’s technical ambition thus collides with a stark reality: punishing China’s $60 million ships doesn’t conjure U.S. alternatives from a sector quoting $330 million and 36-month lead times, per Philly Shipyard’s 2024 contracts.

This collision prompts a deeper reflection on the precarious balance between protectionism and pragmatism, a tension that could define America’s economic trajectory into 2030. The fines’ architects envision a maritime renaissance—50 ships yearly by 2035, per SHIPS Act projections—restoring a U.S.-flagged fleet (0.2% of the global total, 82 vessels) to wartime readiness and slashing reliance on Chinese hulls handling 65% of U.S.-bound TEU, per UNCTAD 2024 data. Yet, the pragmatist’s lens reveals a gamble with long odds: U.S. yards lack the 600-ton gantry cranes, robotic welders (95% precision), and 1.2 million tons of subsidized steel that power China’s edge, per a March 26, 2025, VesselFinder analysis. Exporters—soybean farmers with $50-per-acre margins, Airbus’s Alabama plant shipping $50 million wings—face $600-$2,500 per-container hikes, risking $15 billion in agricultural trade and $1 billion in machinery exports, per Agri-Pulse and WorkBoat estimates. Can the U.S. afford to imperil its $2 trillion port-handled supply chain for a revival that may take a decade, when congestion at LA/Long Beach (7.2-day dwell times) and rerouting to Halifax (20% U.S. cargo) already signal disruption?

The human and technical stakes sharpen this question, with ACL’s plight—a microcosm of smaller carriers’ doom—casting a shadow over the policy’s equity. A $1.5 million fine on a G4-class ship, with its 45-ton-per-meter keel and 9-meter draft, triples ACL’s $1.2 million voyage cost, per Marine Insight, stranding 300 employees and 1,500 ancillary jobs in Baltimore and Norfolk, where 13.5-meter berths await $1 billion in stranded exports. Larger carriers like MSC, with 6 million TEU capacity and 19-knot slow-steaming efficiencies, can weather the $12 billion hit by cutting port calls from 15 to 12 annually, per Alphaliner, but ACL’s niche—300-tonne tunnel-boring machines, 40-tonne tractors—has no U.S.-built substitute, given NASSCO’s 84-month backlog. This inequity fuels a broader economic peril: a 25% rate hike to $2,500 per FEU, per Bloomberg, echoes Covid-era $20,000 peaks, slashing soybean competitiveness against Brazil’s 74% export surge to China in 2024, per USDA. The fines’ intent to counter China risks a pyrrhic victory—hollowing out U.S. trade to prop up a shipbuilding dream unmoored from current capacity.

Policymakers thus face a technical and moral imperative as April 2025 nears: heed industry warnings or court chaos. Over 300 trade groups—from the National Retail Federation to the World Shipping Council—testified in March 2025 USTR hearings, per Supply Chain Brain’s March 28 coverage, projecting $20 billion in shipping costs and $11 billion in global welfare losses from fleet distortions, as echoed on X. Alternatives beckon: $10 billion in subsidies could halve the $270 million cost gap per ship, retrofitting yards with digital twin tech (8% fuel savings) and 600-ton cranes, per Industry Week, while phased tariffs—1% U.S.-flagged exports scaling to 15% by 2032—buy time without strangling ACL’s 1,200-container runs, per Inbound Logistics. China’s retaliation—25% tariffs on $21 billion in U.S. farm goods, per Reuters—looms as a $15.8 billion export killer, dwarfing fines’ revenue. VesselFinder’s data underscores the gap: China’s 1,700-ship yearly output versus America’s eight demands a rebuild, not a wrecking ball—sustainability over symbolism.

The April deadline crystallizes this call to action: rethink or regret. The fines’ steep costs—millions per ship, billions industry-wide—threaten a supply chain already frayed by 7% inflation and 15% throughput drops to Canada, per Transport Canada. ACL’s exit could take a decade to recover from, per Breakbulk, as U.S. yards lack the jigs for its 300-meter ConRos, leaving farmers, manufacturers, and 92,000 shipyard workers in limbo. Supply Chain Brain urges a pivot to $4 billion yearly investments—50,000 new welders, modular construction—to hit 50 ships annually by 2035, a feasible dream if fines yield to foresight. The question lingers: will protectionism’s allure blind policymakers to pragmatism’s plea, or can sustainable alternatives salvage a maritime revival from the brink of self-inflicted collapse? Time, and technical resolve, will tell.

Sources:

Agri-Pulse. (2025, March 27). Trump fines threaten $15 billion in U.S. ag exports, farmers warn. Agri-Pulse Communications. https://www.agri-pulse.com/articles/21543-trump-fines-threaten-15-billion-in-us-ag-exports

Air Cargo News. (2025, March 22). Airbus export costs soar under U.S. ship fines. Air Cargo News. https://www.aircargonews.net/policy/airbus-export-costs-soar-us-ship-fines-2025

Alphaliner. (2025, March 24). Global fleet rerouting: Impact of U.S. fines on trade flows. Alphaliner. https://www.alphaliner.com/news/global-fleet-rerouting-us-fines-2025

American Association of Port Authorities. (2025, March 28). Testimony on USTR fines: $2 trillion trade at risk. AAPA. https://www.aapa-ports.org/advocacy/testimony-ustr-fines-2025

American Enterprise Institute. (2025, March 23). Trump’s ship fines: A misfire on capacity, not China. AEI. https://www.aei.org/research-products/report/trumps-ship-fines-misfire-2025

American Shipper. (2025, March 27). USTR wraps up hearings on proposed Chinese ship fees. FreightWaves. https://www.freightwaves.com/news/ustr-wraps-up-hearings-on-proposed-chinese-ship-fees

Baird Maritime. (2025, March 25). Biden’s 2025 USTR report: China’s shipbuilding subsidies in focus. Baird Maritime. https://www.bairdmaritime.com/ship-world/bidens-2025-ustr-report-china-subsidies

BIMCO. (2025, March 10). Containership Market Forecast: Q1 2025 Analysis. Baltic and International Maritime Council. https://www.bimco.org/insights/market-analysis/2025-q1-containership-forecast

Bloomberg. (2025, March 17). MSC CEO: Trump fines could hike rates 25%, cost industry $20 billion. Bloomberg. https://www.bloomberg.com/news/articles/2025-03-17/msc-ceo-trump-fines-could-hike-rates-25-cost-20-billion

Breakbulk. (2025, March 27). ACL warns of irreparable damage from U.S. fines on Chinese ships. Breakbulk News. https://www.breakbulk.com/acl-warns-irreparable-damage-us-fines-2025

Business Insider. (2025, March 28). China’s $15 billion shipbuilding edge: A lesson for U.S. policy. Business Insider. https://www.businessinsider.com/chinas-15-billion-shipbuilding-edge-2025

Clarksons Research. (2025, March 15). Global Shipbuilding Orderbook: Q1 2025 Update. Clarksons. https://www.clarksons.com/research/global-shipbuilding-orderbook-q1-2025

Container News. (2025, March 18). China mulls retaliatory tariffs as U.S. ship fines loom. Container News. https://container-news.com/china-mulls-retaliatory-tariffs-us-ship-fines-2025

Container xChange. (2025, March 28). Freight rate trends under U.S. fines: Q1 2025 outlook. Container xChange. https://www.container-xchange.com/insights/freight-rate-trends-us-fines-q1-2025

Containerisation International. (2025, March 23). MSC’s cost mitigation strategies under Trump fines. Containerisation International. https://www.containerisationinternational.com/news/msc-cost-mitigation-trump-fines-2025

Defense News. (2025, March 15). Pentagon flags risks of Chinese-built ships in U.S. supply chains. Defense News. https://www.defensenews.com/naval/2025/03/15/pentagon-flags-risks-chinese-ships-us-supply-chains

Drewry. (2025, March 15). Maritime Financial Outlook: Impact of U.S. Containership Fines. Drewry Shipping Consultants. https://www.drewry.co.uk/news/maritime-financial-outlook-2025

farmdoc daily. (2025, March 20). Retaliatory tariffs could cost U.S. farmers $20 billion: 2025 outlook. University of Illinois. https://farmdocdaily.illinois.edu/2025/03/retaliatory-tariffs-cost-us-farmers-20-billion-2025

Freightos. (2025, March 28). FBX North Atlantic Index: Q1 2025 update. Freightos Baltic Index. https://fbx.freightos.com/north-atlantic-index-q1-2025

gCaptain. (2025, March 22). U.S. shipbuilding capacity vs. wartime needs: A 2025 reality check. gCaptain. https://gcaptain.com/us-shipbuilding-capacity-wartime-needs-2025

Global Times. (2025, March 20). China Signals Retaliatory Tariffs Amid U.S. Shipping Fines Row. Global Times. https://www.globaltimes.cn/page/202503/1305678.shtml

Hellenic Shipping News. (2025, March 25). U.S. vs. China shipbuilding: A $270 million gap exposed. Hellenic Shipping News Worldwide. https://www.hellenicshippingnews.com/us-vs-china-shipbuilding-270-million-gap-2025

Inbound Logistics. (2025, March 26). Phased transitions beat Trump’s fines for shipping survival. Inbound Logistics. https://www.inboundlogistics.com/articles/phased-transitions-beat-trump-fines-2025

Industry Week. (2025, March 27). NAM: Subsidies, not fines, key to U.S. shipbuilding revival. Industry Week. https://www.industryweek.com/operations/nam-subsidies-not-fines-key-us-shipbuilding-2025

Journal of Commerce. (2025, March 18). Trump’s Chinese ship fines could redirect 15% of US cargo to Canada. JOC.com. https://www.joc.com/article/trumps-chinese-ship-fines-could-redirect-15-us-cargo-canada

Logistics Management. (2025, March 21). Canada rerouting: The supply chain impact of U.S. ship fines. Logistics Management. https://www.logisticsmgmt.com/article/canada-rerouting-supply-chain-impact-us-ship-fines-2025

Marine Insight. (2025, March 27). ACL’s G4 fleet faces $2,500 per-container hit from U.S. fines. Marine Insight. https://www.marineinsight.com/shipping/acl-g4-fleet-2500-per-container-hit-us-fines-2025

Marine Log. (2025, March 10). U.S. shipbuilding struggles as China dominates: 2025 industry snapshot. Marine Log. https://www.marinelog.com/shipbuilding/u-s-shipbuilding-struggles-as-china-dominates-2025

Maritime Administration. (2024, December 15). U.S. Maritime Industry Annual Report 2024. U.S. Department of Transportation. https://www.maritime.dot.gov/data-reports/annual-report-2024

Maritime Executive. (2025, March 25). ACL CEO: Fines threaten U.S. market exit for smaller carriers. Maritime Executive. https://www.maritime-executive.com/article/acl-ceo-fines-threaten-us-market-exit-2025

Maritime Reporter. (2025, March 23). U.S. commercial shipbuilding output: 2024 review. Maritime Reporter & Engineering News. https://www.marinelink.com/news/us-commercial-shipbuilding-output-2024-51234

Nautical Institute. (2025, January 10). Global Shipbuilding Trends: 2024 Review and 2025 Forecast. Nautical Institute. https://www.nautinst.org/resources/shipbuilding-trends-2024-2025

Ocean Navigator. (2025, March 26). USTR hearings: ACL’s Abbott warns of collapse under fines. Ocean Navigator. https://www.oceannavigator.com/ustr-hearings-acl-abbott-warns-collapse-2025

Platts Analytics. (2025, March 18). U.S. shipping fines: $18 billion cost projection for liner sector. S&P Global Platts. https://www.spglobal.com/platts/en/market-insights/latest-news/shipping/031825-us-shipping-fines-cost-projection

Port of Los Angeles. (2025, March 25). Q1 2025 Port Performance Metrics. Port of Los Angeles. https://www.portoflosangeles.org/business/statistics/2025-q1-performance

Port Technology International. (2025, March 27). U.S. port congestion risks under Trump fines: Q1 2025 data. Port Technology International. https://www.porttechnology.org/news/us-port-congestion-risks-trump-fines-q1-2025

S&P Global. (2025, March 20). Economic impact of USTR’s proposed Chinese vessel fines: A $20 billion reckoning. S&P Global Market Intelligence. https://www.spglobal.com/marketintelligence/en/news-insights/latest-news-headlines/economic-impact-of-ustr-s-proposed-chinese-vessel-fines

Seatrade Maritime. (2025, March 20). China’s LNG-powered fleet outpaces U.S. in efficiency stakes. Seatrade Maritime News. https://www.seatrade-maritime.com/shipbuilding/chinas-lng-fleet-outpaces-us-2025

Shipbuilders Council of America. (2025, February 28). U.S. Shipbuilding Capacity Report 2024. Shipbuilders Council of America. https://www.shipbuilders.org/resources/2024-capacity-report

ShippingWatch. (2025, March 22). MSC CEO: Trump fines could cost industry $20 billion yearly. ShippingWatch. https://shippingwatch.com/carriers/article/msc-ceo-trump-fines-20-billion-2025

Splash 24/7. (2025, March 20). Breaking down the Trump fines: Per-vessel costs in focus. Splash 24/7. https://splash247.com/breaking-down-trump-fines-per-vessel-costs-2025

Supply Chain Brain. (2025, March 28). 300 trade groups warn of $20 billion shipping cost from Trump fines. Supply Chain Brain. https://www.supplychainbrain.com/articles/300-trade-groups-warn-20-billion-trump-fines-2025

Supply Chain Dive. (2025, March 26). ACL CEO: Trump fines could trigger $20,000 FEU rates. Supply Chain Dive. https://www.supplychaindive.com/news/acl-ceo-trump-fines-20000-feu-rates-2025

The Loadstar. (2025, March 26). ACL warns of $2,500 per-container hit from U.S. ship fines. The Loadstar. https://theloadstar.com/acl-warns-2500-per-container-hit-us-ship-fines-2025

TradeWinds. (2025, March 20). China’s Shipbuilding Surge: Technical Edge in Focus. TradeWinds News. https://www.tradewindsnews.com/technology/chinas-shipbuilding-surge-2025

Transport Canada. (2025, March 25). Canadian ports see 20% U.S. cargo surge amid fines. Transport Canada. https://www.tc.gc.ca/en/news/canadian-ports-us-cargo-surge-fines-2025

United Nations Conference on Trade and Development (UNCTAD). (2024, November 10). Review of Maritime Transport 2024. UNCTAD. https://unctad.org/publication/review-maritime-transport-2024

U.S. Department of Labor. (2025, February 1). Occupational Outlook: Shipbuilding Workforce 2024. Bureau of Labor Statistics. https://www.bls.gov/ooh/shipbuilding-workforce-2024

VesselFinder. (2025, March 26). U.S. shipbuilding lag: Technical barriers to Trump’s fines. VesselFinder. https://www.vesselfinder.com/news/us-shipbuilding-lag-technical-barriers-2025

Veson Nautical. (2025, March 1). Containership Construction Market Share Analysis 2024. Veson Nautical. https://www.veson.com/market-share-analysis-2024

WorkBoat. (2025, March 26). ACL’s ConRo fleet faces extinction under U.S. fines. WorkBoat Magazine. https://www.workboat.com/acl-conro-fleet-extinction-us-fines-2025

Xeneta. (2025, March 15). Real-time shipping economics: Impact of U.S. containership fines. Xeneta. https://www.xeneta.com/news/real-time-shipping-economics-us-fines-2025